–airHome: a 6-step journey to Premium Quality

Like all Hitachi air conditioners, the airHome range of residential mini-splits follow a strict global quality protocol, originating from our Japanese quality engineers with world-class manufacturing expertise.

From design through to manufacturing, airHome air conditioners pass extensive testing and inspections. Only this way can we ensure that every airHome unit will deliver the comfort you deserve, providing your home with premium cooling and heating for years to come.

Here are the 6 steps that each airHome air conditioner goes through!

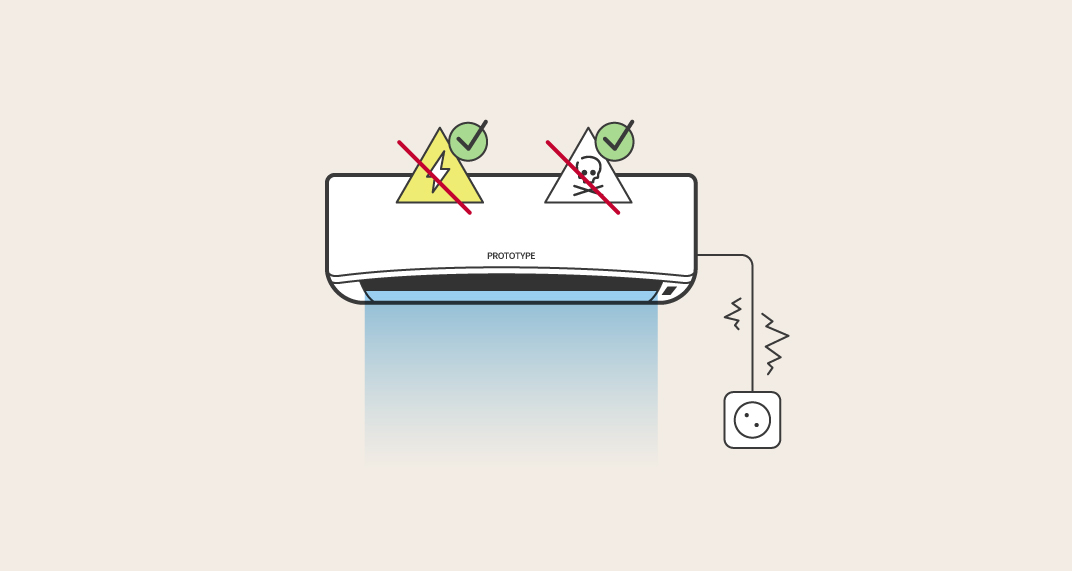

1- Safety stress tests

*All images are for illustration purpose only and do not accurately represent the testing methods.

Product prototypes are examined in all aspects and thoroughly tested with product safety being paramount. A series of ‘stress tests’ that include extreme voltage and electrical shocks make sure that your airHome won’t cause danger for users or their homes.

"We are committed to using a fireproof metallic box to enclose the electronic components in all airHome outdoor and indoor units. Surpassing international standards, using metal instead of plastic eliminate the risk of fire spread". Hiroyasu Minowa, Director, Global Quality Assurance

To further enhance fire safety, Hitachi residential air conditioners use metal instead of flame-retardant resin in key areas.

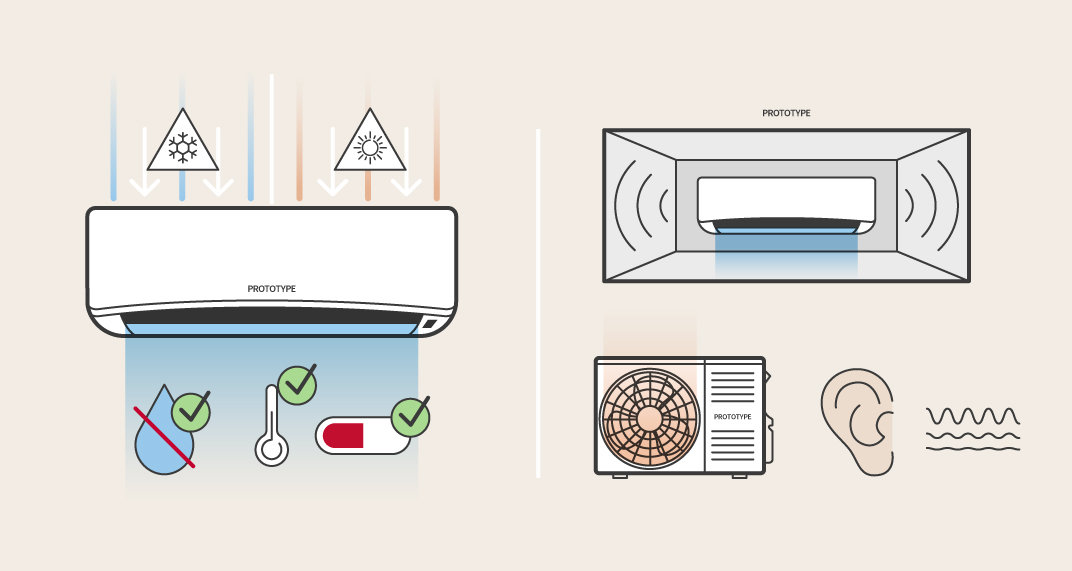

2- Cycle tests simulating critical conditions

Prolonged ‘Cycle tests’ are run in our certified labs to repeat a large variety of critical conditions such as high humidity and extreme temperature levels for each region, such as 55˚C for cooling in high ambient regions and -30˚C for the low-ambient heat pumps.3

“In Japan we’re accustomed with very humid and hot summers. If not properly designed, air conditioners may not be able to withstand such conditions. Condensate waters may leak. That’s why we’ve developed a stringent ‘sweat test’ at 85% RH (residual humidity rate)”.

Hiroyasu Minowa, Director, Global Quality Assurance

For quiet comfort, all Hitachi room air conditioners pass best-in-class acoustic tests, in which sound levels and vibrations are thoroughly measured and analyzed.

3- Certified product energy-efficiency ratings

Once the final design of the air conditioner is decided, sample units are provided to labs with certified competence for the testing and verification of specifications and energy efficiency levels, based on regulation and international standards.

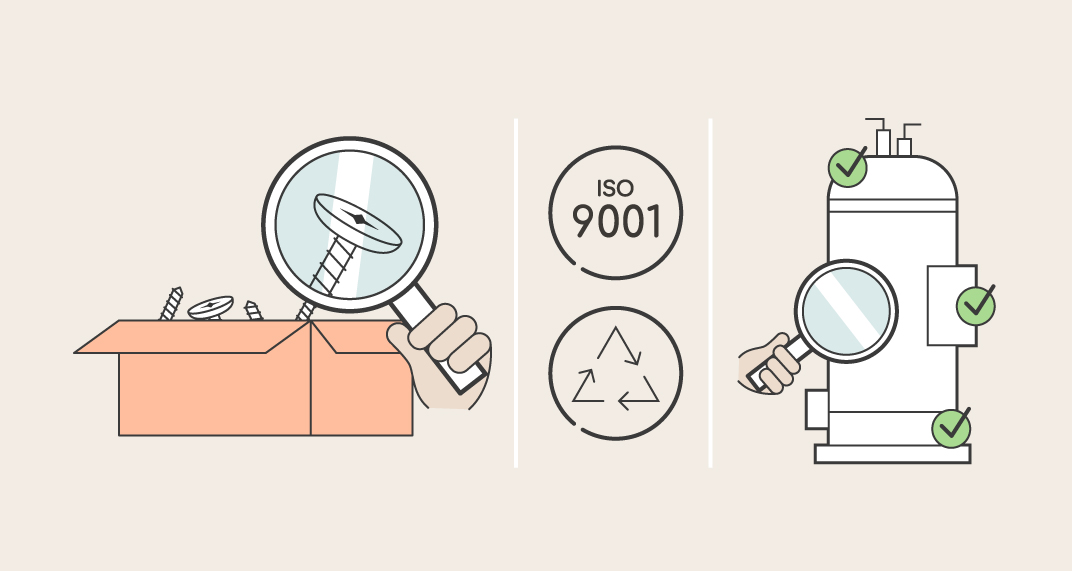

4- Components inspection

All parts and components of airHome air conditioners, from small screws to larger components like compressors, are inspected by quality specialists. All our suppliers are ISO-9001 certified and must comply with Hitachi Group’s Sustainable Procurement Guidelines.

The most critical components endure multiple tests, such as DC fan motors being subjected to no less than 19 tests! In total, over 140 test protocols have been designed for Hitachi air conditioning components.2

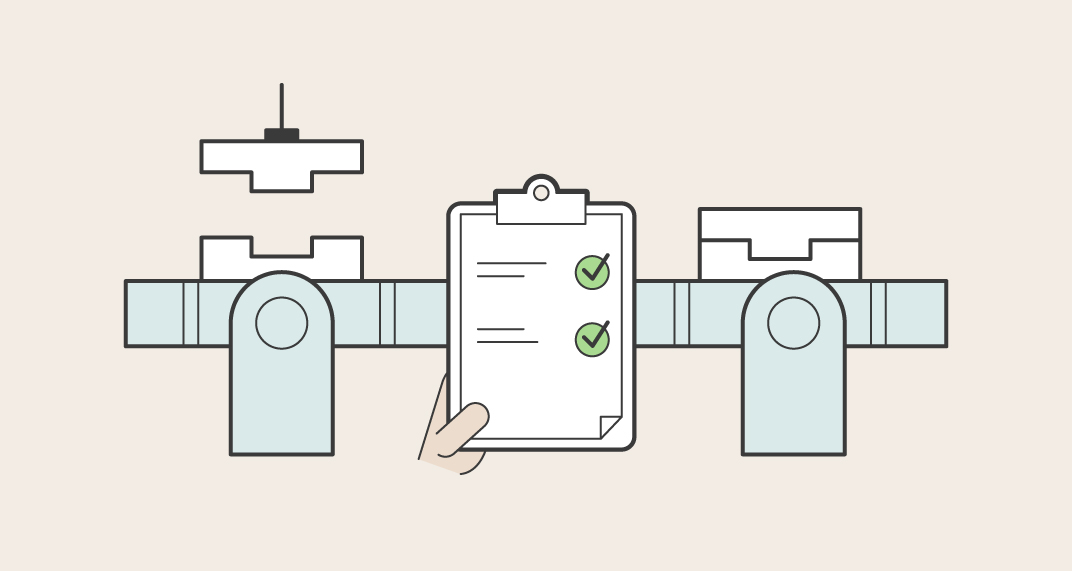

5- During production

Each assembly step is followed by a validation test. Only when the previous step has been validated through inspection or testing, then the product can go on to the next assembly step.

For example, one key assembly step of an air conditioner consists in brazing to weld the refrigerant pipes with the condenser or evaporator.

To make sure the brazing is properly done, every loop assembled after brazing is subject to a complete leak check. The leak test is done by charging the assembled loop with nitrogen or helium gas. Then the system is placed in high-precision gas chamber that can detect nitrogen or helium gas leaks.

"In Japanese Kaizen philosophy, we must strive to continuously learn and improve. We collaborate with all airHome manufacturing sites to improve our quality methods".

Hiroyasu Minowa, Director, Global Quality Assurance

6- At the end of production: 100% of units tested

This is why you can rely on airHome: every single unit is switched on and tested once it’s been completely assembled. That means, the airHome you have at home has been specifically tested to guarantee that it will effectively cool (or warm) your room.

Here’s an example of final ‘functional tests’ for indoor units:

• Low-noise operation and vibrations

• Wifi connectivity (if embedded wifi feature)

• Flawless communication with the remote controller & timer functionality

• Fan rotation to generate the airflow

And example of final ‘functional tests’ for outdoor units:

• Low-noise operation and vibrations

• Connection with an indoor unit for testing

• Heating output

• Cooling output

• Power input

With these 6 steps in place, Hitachi guarantees that your airHome is the best airHome for you, whether for an installation or to install in your own home, offering the Japanese Premium Quality that all Hitachi air conditioning products offer.

Footnotes

(1) Applies to the majority of airHome air conditioners in the world.

(2) For components of airHome range and other Hitachi Cooling & Heating ranges.

(3) The temperatures of critical ambient testing vary per region.

by Hitachi

14 Jan 2025